KNOW WHAT MATTERS!

The THOMSIT core range is reduced to the essentials and offers everything you need. It covers more than 90 % of your tasks during floor installation and makes it easier than ever for you to choose the right product. Without you having to sacrifice product safety, working comfort or efficiency.

STEP BY STEP TO THE PERFECT FLOOR!

Assessing and preparing

- THOMSIT RS 100

- THOMSIT R 729

Priming

- THOMSIT R 766

Levelling

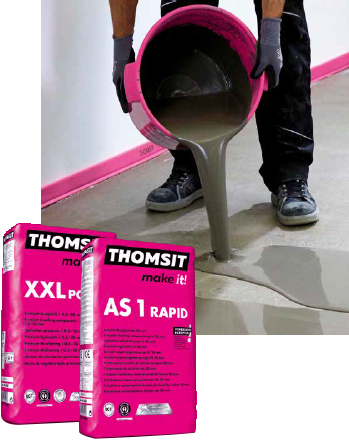

- THOMSIT XXL POWER

- THOMSIT AS 1 RAPID

Bonding

- THOMSIT K 190 F

- THOMSIT P 680 ELAST STRONG

- THOMSIT UK 840

ASSESSING AND PREPARING

Start by assessing the condition of the subfloor. It must be firm, load-bearing and dry. Then remove old, adhesion-inhibiting surface layers. If there are cracks in the substrate, mix the two components of THOMSIT R 729 Silicate Casting Resin and fill the cracks directly from the practical application bottle. For filling holes and levelling height differences, use THOMSIT RS 100 Rapid Repair Mortar with adjustable consistency: from stiff to flowable.

Fast. Efficient. Adjustable.

THOMSIT R 729

Our Silicate Casting Resin helps you fill all cracks in record time!

- Easy and perfect dosing

- Fast curing

- Can be mixed without stirring device

Fine. Fast. Non-Slump.

THOMSIT RS 100

With this filler everything goes smoothly!

- Rapid repair mortar that can be leveled to zero mm

- Can be easily smoothed and molded to the surface (one smoothing is enough)

- Leaves no visible edges

- Suitable for every layer thickness range

The requirements:

Surface stability

Intensive grinding removes adhesion-inhibiting surface layers like residues of old installation materials. The aim: to produce a stable and reliable basis for the following steps.

Cleanliness

A clean surface is a must. Remove dust with a professional vacuum cleaner to ensure sufficient adhesion of the following layers. If there are stubborn dust deposits, light sanding is often enough.

This is how you prepare the subfloor:

Cracks

Cracks in the substrate need to be closed by forcefit bonding according to the recognized rules of the trade. For this purpose, mix the two components of THOMSIT R 729 Casting Resin and fill the cracks

directly from the practical application bottle. Sprinkling with quartz sand improves the adhesion of subsequent layers.

Surface irregularities

Spalls, i.e. broken out areas, need to be filled, height differences must be levelled. These are standard floor layer‘s tasks. Fast-setting repair mortar THOMSIT RS 100 offers you an adjustable consistency: from stiff to flowable.

AND THAT‘S HOW IT WORKS!

1 Take a good look at the subfloor. Is it load-bearing and dry? Unstable, crumbling surfaces should be milled or sanded and afterwards cleaned.

2 If there are cracks, widen them with a grinder or mill. If necessary, reinforce them by inserting the screed clamps supplied with THOMSIT R 729.

3 Fill component B (hardener) of THOMSIT R 729 Casting Resin into the bottle with component A (resin).

4 Vigorously shake the bottle to mix the two components. Cut open the nozzle and fill the resin into the crack.

5 Use THOMSIT RS 100 Rapid Repair Mortar to level out differences in height between two adjacent rooms or to fill larger holes in the substrate.

PRIMING

Substrate absorbency has a considerable influence on the subsequent levelling compound: too rapid loss of water may, for instance, cause cracks. Use of a primer such as THOMSIT R 766 is therefore a matter of course for you.

But the primer not only adjusts the substrate absorbency. It also boosts the adhesion of subsequently applied levelling coats – even on very smooth substrates like ceramic tiles.

Multi-purpose use. Fast drying. High yield.

THOMSIT R 766

This multi-purpose primer helps you achieve optimum surface conditions for virtually all substrates.

- Very fast drying

- Highly concentrated with a very high yield

- Multi-purpose use on absorbent and impervious substrates

- Colored primer, therefore easily visible on the surface

Multi-purpose use on many different substrates:

Cement screeds / calcium sulfate screeds

Residues of old installation materials

Tiles / natural stone

Wood (floorboards, OSB boards)

AND THAT‘S HOW IT WORKS!

1 Remove loose dirt from the substrate surface.

2 Prime the substrate with THOMSIT R 766: on absorbent surfaces diluted with water at a ratio of 1:4, on non-absorbent substrates at a ratio of 1:1. On reaction resin layers, use R 766 undiluted.

3 Apply a uniform coat of THOMSIT R 766 with a lambskin roller.

LEVELLING

Smoothing the substrate with a suitable levelling compound is of key importance. In this way, you produce optimum installation conditions for the selected floor covering. You facilitate adhesive application and reduce adhesive consumption. The result: uniform substrate absorbency that is required for expert bonding. Carpets and other resilient floor coverings can be fixed much more easily and safely.

Powerful. Ultrasmooth. High strength.

THOMSIT XXL POWER

Our premium levelling compound enables you to produce ultra-smooth but very strong surfaces – especially in areas subject to high loads and stresses.

- Rapidly ready to receive flooring

- Ultra-smooth surfaces help you save adhesive

- Also suitable for use in shops, hospitals and industrial environments

Fast. Strong. Tension-free.

THOMSIT AS 1 RAPID

With this calcium sulfate-based levelling compound, you can even tackle difficult substrates!

- Virtually tension-free

- High strength

- Ultra-smooth surfaces for low adhesive consumption

The choice of levelling compound depends on the type of substrate:

THOMSIT XXL POWER

Cement screeds

Tiles

Waterproof old adhesives

THOMSIT AS 1 RAPID

Calcium sulfate screeds

Mastic asphalt screeds

Chipboards / OSB boards / dry screeds

AND THAT‘S HOW IT WORKS!

1 Choose a suitable levelling compound. Mix it with a stirring device to produce a homogeneous, lump-free mixture.

2 Pour the levelling compound onto the substrate.

3 Spread it evenly with a notched squeegee.

4 Finish the freshly levelled area with a spiked roller to obtain a particularly smooth surface.

BONDING

The adhesive creates a firm bond between the floor covering and the substrate. Adhesive bonding is therefore the method of choice if you want to create a floor structure with a service life of many years. Durable and resistant – even when exposed to loads from chair castors. In certain cases, floor coverings can be fixed by dry bonding for easy removal at a later date. Or they are fixed with an anti-skid tackifier to ensure slip resistance. Before tackling such special tasks, best talk to your THOMSIT expert. He will show you the right solution for every application and provide active support.

Shear-resistant. Fiber-reinforced. Economical.

THOMSIT K 190 F

Your fiber-reinforced power adhesive for the secure bonding of resilient flooring!

- Extremely low consumption – high yield

- Short flash-off time

- High shear strength, hard adhesive bed

Multi-purpose. Efficient. Unique.

THOMSIT UK 840

Your powerful multi-purpose adhesive for tackling almost every task!

- Powerful adhesion, suitable for many different floor coverings

- Extremely wide range of applications

- Economical “one-for-all” solution

Powerful. Versatile. Durable.

THOMSIT P 680 ELAST STRONG

Your universal hero for a wide range of applications and all types of parquet!

- With VISCO-FLEX technology:

- Excellent spreadability

- Very good ridge formation

- Hard-elastic bonding to ensure a reliable, long-lasting bond

- Extra high early strength – saves you time

- Adhesive residues can be easily removed

The proper choice of adhesive depends on the type of flooring:

PVC flooring (e.g. luxury vinyl tiles) and rubber flooring

THOMSIT K 190 F

Carpeting and needle punch, CV and linoleum flooring

THOMSIT UK 840

All types of parquet

THOMSIT P 680 ELAST STRONG

AND THAT‘S HOW IT WORKS!

Luxury vinyl tiles (LVTs)

1 Apply THOMSIT K 190 F with trowel of notch size A2. Only apply as much adhesive as can be covered with flooring while the adhesive is still wet.

2 After a short flash-off time, place the tiles into the adhesive bed and press them down to ensure good adhesive transfer.

Carpeting and needle punch, CV and linoleum

1 Depending on the texture of the backing, choose notch size B1 or B2 for applying THOMSIT UK 840 adhesive.

2 After approx. 10 minutes flash-off time, place the textile flooring into the still wet adhesive. Carefully press the flooring down.

Parquet

1 Apply as much THOMSIT P 680 ELAST STRONG with a suitable notched trowel as can be covered with parquet within the open time.

2 Ensure good adhesive transfer to the underside of the parquet and avoid gluing the edges. Observe a minimum wall distance of 10 mm.